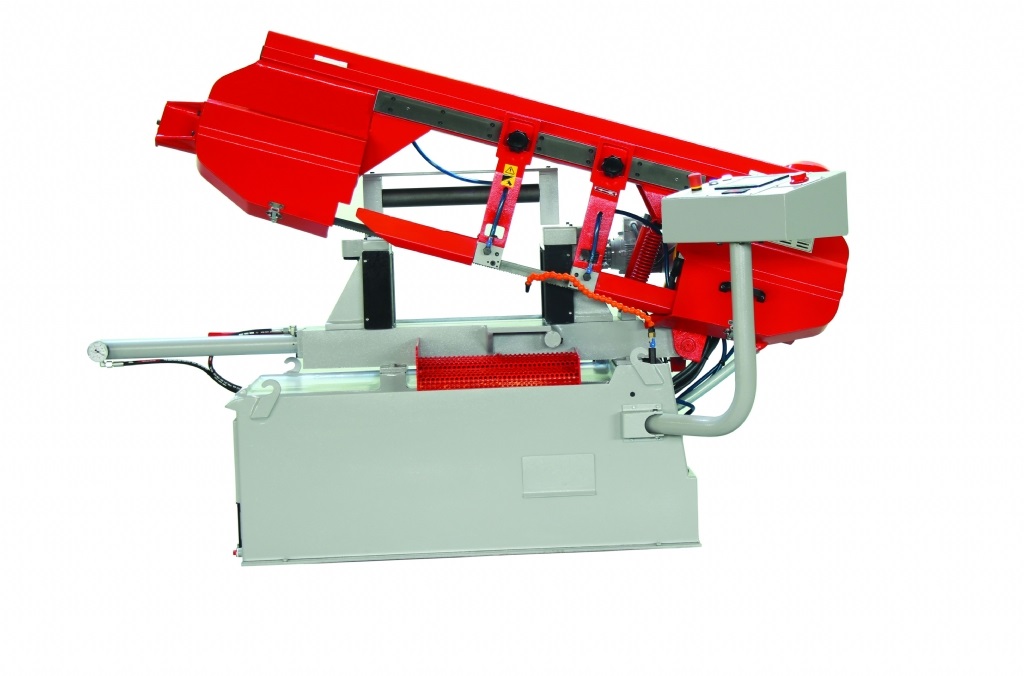

Automatic Bandsaw for Metal Cutting

Electrical band saws are manufactured in our own factory, with the cutting capacity to 250 mm x 250 mm. It works also in manual and automatic mode, with and without angle

The production program of the band saws designed for metal cutting ranks the company EMS Metalworking Machinery among the world`s largest producers regarding both product range as well as production volume. The production program of the band saws designed for metal cutting offers more than 40 types of machines: manual, gravity and semi-automatic band saws, as well as fully automatic CNC machines. In our portfolio, you can find band saw with a swing arm of the saw blade as well as a 2-column type. All machines are distinguished by extraordinary robust construction in combination with the use of latest trends and practices. All machines are equipped with electric drives and electrical, electronic and hydraulic components from renowned European producers. All of this ensures maximum cutting accuracy, along with a long service life of the machines and the saw blades.

Silent run

Stable cast execution

Lowering of the saw arm via hydraulic cylinder with throttle valve infinitely adjustable

Micro switch for automatic limit switch

Easy to read scale for angle adjustment

As standard with high-quality bi-metal saw band

Saw band tension adjustable on the front side via handwheel

Ball bearing saw band guide

Robust machine base with large wheels and handy transport handle for easy location change of the machine

Adjustable material stop for serial work

Circuit breaker for the belt cover

Fully equipped, allowing the user to be productive immediately after commissioning

In Detail

The EMS BS200 metal cutting bandsaw is robust and quite compact for the cutting capacities. It is suitable for use in fabrication workshops, engineering workshops and general factory use. The chassis and arm are stiff cast iron giving great strength and accuracy in the cut, whilst the welded steel base houses a coolant pump system and the electrical controls. The 1.1kW motor drives the blade through a choice of 4 speeds for a wide range of cutting tasks. The cutting bow has a hydraulic down feed control ram with a feed rate selection dial and lock off control mounted on the switch panel. A comprehensive guide system holds the blade securely so that accurate cuts are made every time. A blade tension indicator is part of the tensioning system for accurate tension setting. The vice has a clever setting latch plus the rear jaw can be swivelled for bevel cuts. Safety interlock switches prevent the machine being run whilst the blade access doors are open. Coolant is supplied to both sets of guides, the flow rates can be set using the lever valves. This is a well engineered machine that will do the job every day.

Key Features

Vice jaws swivel for bevel cuts, quick action jaws for fast clamping

Built-in coolant system to prolong blade life and give a cleaner cut

4 blade speeds, enable a speed to be chosen to suit the task

Double row ball bearing blade guides, hold the blade securely

Fully adjustable downfeed hydraulic damper with setting control

RECOMMENDATIONS WHEN CHOOSING A BAND SAW FOR METAL CUTTING

The main, essential criterion for the choice is the size of the saw blade.

Saw blades are manufactured in the following standard sizes: 13x0,65; 20x0,9; 27x0,9; 34x1,1; 41x1,3; 54x1,6; 67x1,6...

In general, the larger the diameter of the material, and the greater the volume of the cut pieces - the bigger the saw blade.

As an example, we will use full material with a diameter of 100 mm, grade 11 600, DIN ST 60-2.

1. Individual pieces in a month

Saw blade 13x0,65 mm, manual band saw for metal cutting, cutting time approx. 9 min.

This saw blade is not manufactured in higher quality, M 51, that is suitable for cutting of high-grade materials.

2. Dozens of pieces per month

Saw blade 20x0,9 mm, gravity band saw for metal cutting, cutting time approx. 4 min.

This saw blade is not manufactured in higher quality, M 51, that is suitable for cutting of high-grade materials.

3. Hundreds of pieces per month

Saw blade 27x0,9 mm, gravity band saw for metal cutting, or the hydraulic-gravitational type H., cutting time approx. 2,5 min.

Starting from this size, the saw blades are manufactured in many tooth designs that enable cutting of all material types.

Saw blade 34x1,1 mm, gravity band saw, cutting time approx. 2 min. Cutting in bundles possible.

4. Approx. thousands of pieces per month

Saw blade 27x0,9 mm, semi-automatic band saw for metal cutting or CNC automatic machines, cutting time approx. 2 min.

Saw blade 34 x1,1 mm, semi-automatic band saw plus, 2-column semi-automatic or 2-column CNC automatic, cutting time approx. 1,5 min. Cutting in bundles possible.

5. Thousands of pieces per month

Saw blade 34x1,1 mm, band saw for metal cutting 2-column CNC automatic machine, cutting time approx. 1 min. Cutting in bundles is possible.

Cutting times are indicative. They depend on the tooth size, optimum cutting speed, and wear of the saw blade. There is a number of options here. The choice depends on the overall range of the material. There are usually more options for the choice of the size and type of the band saw, which also implies the price of the machine. Our specialists of the Sales Department will be happy to help you with the selection of the optimal band saw according to your needs.